LiqTech Strengthens Position in Large-Scale Produced-Water Reuse with QureFlow™ Max

Launching at the Produced Water Society Conference, reinforcing LiqTech’s position as a technology-led provider

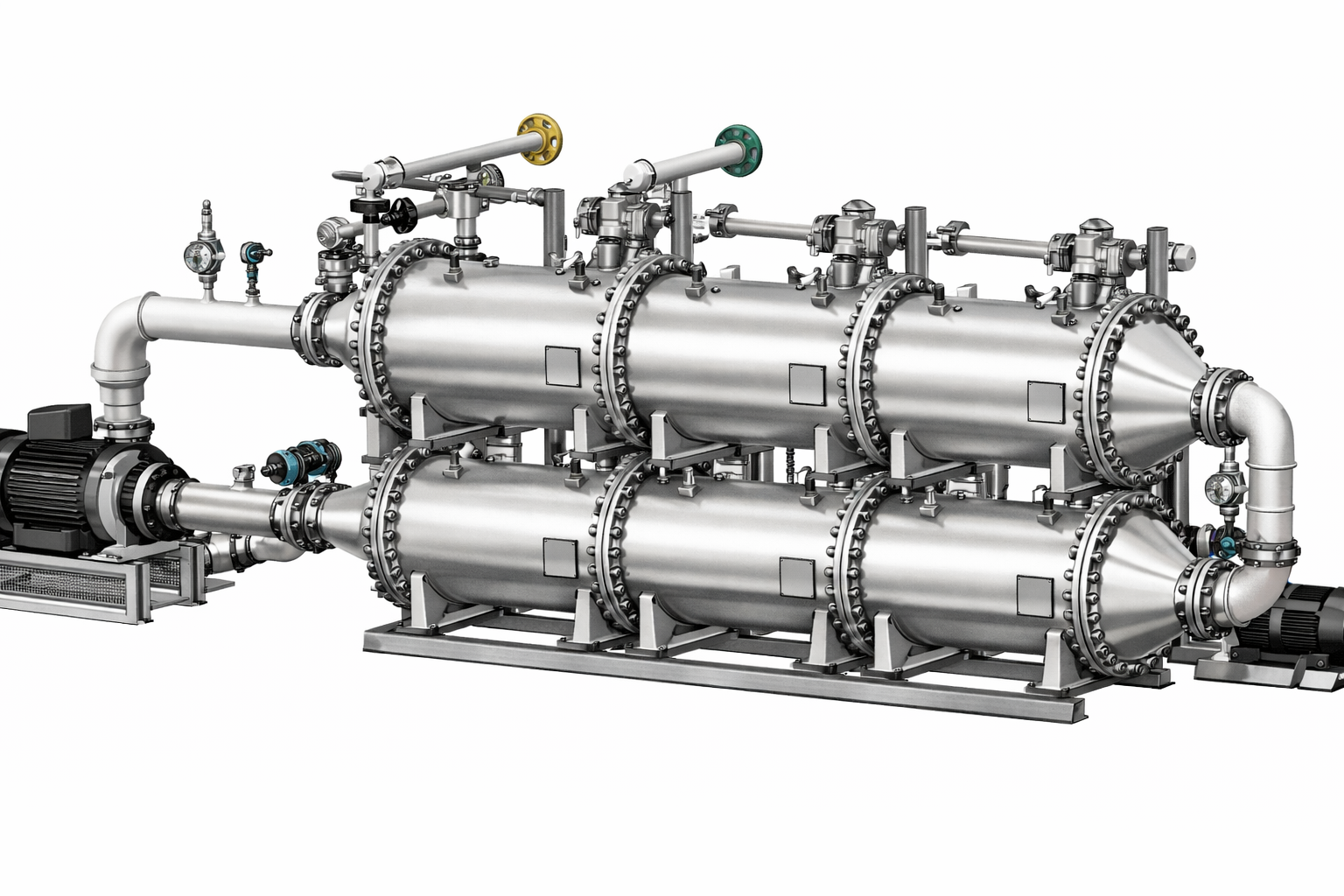

SUGAR LAND, TX, UNITED STATES, February 4, 2026 /EINPresswire.com/ -- LiqTech International Inc. (NASDAQ: LIQT), a specialist in advanced ceramic filtration technologies, will be launching its QureFlow™ Max produced-water treatment system at the 36th Annual Produced Water Society Conference, being held February 9–12, 2026 in Sugar Land, Texas.QureFlow Max is the largest and highest-capacity system within LiqTech’s QureFlowTM platform, purpose-built for upstream produced-water applications where water volumes, variability, and uptime requirements exceed the limits of conventional treatment technologies. Designed specifically for large-scale reuse operations, the system addresses a critical challenge in produced-water strategies: reliable removal of oil and suspended solids under highly variable operating conditions.

The system enables recycling and reuse and also serves as pretreatment ahead of desalination where required. QureFlow Max does not desalinate water. Instead, it operates in the oil and total suspended solids removal layer where treatment technologies are most actively evaluated, and where reuse strategies most often succeed or fail.

“Produced-water reuse has shifted from a sustainability ambition to an operational requirement,” said Tobias Baldrian Madsen, Senior Vice President Commercial at LiqTech. “The limiting factor is rarely desalination. More often, it is achieving consistent oil and solids removal under real-world conditions. QureFlow Max was developed to address this challenge at scale, providing a stable, technology-led alternative where conventional systems struggle with variability, oil spikes, fouling, and frequent intervention.”

Designed for very high flow and uptime-critical operations, QureFlow Max represents the highest throughput configuration within the QureFlowTM suite. The system is available in high-capacity, skid-based configurations with four or six installed membrane vessels per skid. Each skid delivers feed capacities of 80-120 m³/h, equivalent to 350-530 gpm (gallons per minute) or 12,000-18,000 BWPD (Barrels of Water Per Day), supporting large-scale produced-water reuse where throughput, stability, and operational reliability are essential.

QureFlow Max is built on LiqTech’s silicon carbide ceramic membrane technology, offering high chemical resistance, mechanical strength, and durability in harsh produced-water environments. The system is designed to operate reliably in waters characterised by high total dissolved solids, elevated temperatures, variable oil content, and fouling and fouling-prone feed streams, making it well suited to reuse-focused North American operations.

At the conference, LiqTech will present field validation data from North American produced-water operations, demonstrating QureFlow Max’s ability to consistently remove more than 99 percent of oil and suspended solids while maintaining stable performance despite fluctuating feed conditions, including changes in oil concentration, water chemistry, temperature, and flow.

QureFlow Max is engineered for modular deployment and automated operation, supporting both fixed and mobile reuse configurations. The system is available in unclassified or ATEX Zone 2 / C1D2 configurations, features remote control and fully automated operation, and is designed to integrate seamlessly into existing produced-water infrastructure without altering upstream or downstream processes.

Unlike service or water-midstream providers, LiqTech offers QureFlow Max as a proprietary treatment technology. In many applications, it acts as pretreatment ahead of desalination. In others, such as hydraulic fracturing reuse loops, it serves as the core treatment step, where clear brine quality is sufficient for reuse.

“In produced-water systems, oil and solids removal is where reuse strategies succeed or fail,” said Brent Halldorson, Produced Water Expert, United States, LiqTech. “Operators need technologies that can handle unstable feed water without constant attention. QureFlow Max delivers consistent separation performance during upset conditions, helping maintain uptime, protect downstream processes, and reduce reliance on freshwater.”

LiqTech will be on site at the Produced Water Society (PWS) Conference. Attendees are invited to meet LiqTech’s experts to discuss scalable, reliable produced-water treatment and reuse. As a critical technology layer in the produced-water treatment chain, LiqTech welcomes collaboration with operators, integrators and partners looking to strengthen their water-treatment and reuse solutions.

About LiqTech International, Inc.

LiqTech International, Inc. (NASDAQ: LIQT) is a clean technology company specialising in advanced ceramic filtration solutions for water treatment applications. With deep expertise in materials science and engineering, LiqTech develops proprietary filtration technologies for challenging industrial water environments. The company’s core focus areas include produced-water recycling and reuse, industrial wastewater treatment, and marine water treatment. LiqTech is headquartered in Ballerup, Denmark, with operations across North America, Europe, and Asia.

For more information, please visit www.liqtech.com.

All media enquiries to be directed to:

Susan Keegan Elleskov

LiqTech Holding A/S

ske@liqtech.com

+45 31 23 29 45

Shreyasi Bhaumik

BCM Public Relations Ltd

s.bhaumik@bcmpublicrelations.com

+44 (0) 203 965 7410

-ENDs-

Shreyasi Bhaumik

BCM Public Relations Ltd.

+44 20 3965 7410

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.